Construction time again

Wheels, sliced bread, gravity. No point in trying to re-invent them. I'm not creative enough or committed enough to publish ground-breaking new research, discover fundamental truths about the human condition or reassemble a disassembled clothes peg. I do like to build and own nice things though, so my philosophy in this regard comes down to seeking out the very best of other peoples' work, and then copying it. I'm very happy to give all the credit that's due, as long as I get to keep the shiny thing that I produce.

Thankfully, in the amateur radio world, I'm discovering that this approach works out pretty well due to the unselfish and benevolent nature of the people that wear the mantle.

I came across a chap called Ian White GM3SEK giving a lecture on good RF housekeeping at an RSGB convention. It was very inspiring, and I built one of the mains filters he championed. I'll write that up another time, but his website led me to rediscover the work of another guru, Steve Hunt G3TXQ, who also had an impressive website. I remember it well, because Steve is sadly no longer with us, and he rather emotionally wrote about his deteriorating health on his blog. You can view the whole site at www.karinya.net

It's great that the site has been kept operational by those he left behind, as it's a really positive legacy. Highlighted there is one of the best technical papers I've read during my training, which I'll link to at the end of this article. It's on getting the most out of an RF choke across the amateur HF bands - hence this project. Why wouldn't you build one? Give yourself the best chance, I say.

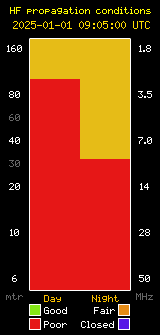

I'll let you read the paper in your own good time - it's almost compulsory I would suggest - but here's the spoiler.

Just take a moment to suck all that up. What a great reference image. Unless you have specific requirements below 7MHz, just build the best. Nine turns of 50Ω coax on three FT240 52-mix ferrite toroids. So I did.

Parts list

Ferrite Toroids: Fair-Rite 52 mix 12.7mm x 60mm - available from Mouser

Coax Cable: TWO metres of RG142 High Power 50R Coaxial Cable - available from Enigma-Shop

Enclosure: Fibox PC 95/75 HG 100mm x 100mm x 75mm in UV Stable Polycarbonate - available from Farnell

Coaxial Sockets: Amphenol 83-1R (SO239) - available from Farnell

Stainless Steel M3 nuts (nyloc) & bolts: eBay, Amazon, wherever.

Get on with it

I'm not going to drag this out.

I'm not going to drag this out.

Apply a few drops of super-glue between each of the toroids and stick them together. Let it dry for a few minutes. You can tape them with something like PTFE tape instead if you think you might want to re-use them individually for something else later, otherwise this becomes a permanent marriage.

Why did I choose RG142? I don't intend to run a lot of power through this, but it would nice to have the option in the future. I also don't want to ever have to worry about how hot it's getting, so I went with the high-power capable option given my limited knowledge about these things. Now, to make life a little bit easier for myself further down the line, I decided to solder the 3mm shield tag (which bolts to the SO239 chassis-mounting point) before I started. I'm not sure this made any difference to be honest. I was worried that soldering the relatively small diameter RG142 core into a big 'ole SO239 socket was going to be tricky, mechanically speaking. Turned out not to be the case at all. Other factors would make this seem like a walk in the park. More on this later.

Wind 9 turns of the coax around the tri-toroid creation. You can wind it quite tightly without risk of 'collapsing' the dielectric and causing a pinch-point. I used a 'crossover' mid-wind to allow the two 'tails' to stick out on opposing sides of the resulting choke.

Wind 9 turns of the coax around the tri-toroid creation. You can wind it quite tightly without risk of 'collapsing' the dielectric and causing a pinch-point. I used a 'crossover' mid-wind to allow the two 'tails' to stick out on opposing sides of the resulting choke.

Don't forget, each time the coax passes through the centre equals one 'turn' - whichever orientation or winding pattern you use.

You may want to avail yourselves of the extra hand offered by numerous cable ties. Whilst winding as tightly as you need isn't an issue, having the whole lot unravel in an instant if you let any part of it go is a distinct possibility. Employ the first cable ties early, liberally, and as soon as you get the ninth turn completed. You can always snip off those you don't need later.

Size matters

So, I know you counted the turns, right? Because you're reading an article about winding an RF choke? Sure, I get it. I can count too, and my choke only has eight turns. I could have left it - I'm sure it would probably have done a reasonable job, but I'm just not made like that. One metre of RG142 isn't quite enough for nine turns on three toroids. Unfortunately, at my chosen supplier, it's only sold by the metre, so make sure you order TWO metres like I did at the second time of asking.

OK, now let's put that lot aside and turn to the enclosure work.

I should say that I chose this box because I liked the construction quality, the sturdy lid-clamping bolts (they may look flimsy, but they are actually really substantial, and are semi-retained in the lid to avoid misplacement) and the IP67 rating. I also spent the additional money on the polycarbonate version as I want the option of leaving it outside for an extended period of time.

Mark and drill the enclosure to take the SO239's. I chose to fit mine in the middle of the lower half of the Fibox enclosure. With hindsight, it may have been better to fit them higher up to make it easier to solder the SO239 connections - I'll never know now. I used the trusty step drill to punch the two 16mm holes (I didn't quite drill the full depth - just enough to properly seat the sockets) and a 3mm drill for the mounting bolt holes. The polycarbonate machines well - it's fairly hard material. If you don't have step drills, then you should consider getting a set. They are just so useful for all manner of things.

Ah, and it was all going so well...

Bringing the whole lot together was a bit of a nightmare. I'm not really sure why it was so hard. Maybe the box wasn't quite big enough, or that RG142 wasn't the right choice of coax. It's certainly a handful to work with once coiled. I also found that the most frustrating part was soldering the centre core of the second socket connection. Not enough room to work, the soldering iron kept touching the box (burning polycarbonate - aromatic...) my fingers (past caring at this point) and the plastic dielectric and outer protective coax sleeve.

I gave up when the centre core snapped off at the end of the exposed dielectric for the third time. It's really brittle - you only get to bend it twice before it breaks off. My solution was to cut two additional sections of the inner core out of the spare coax I had, and pre-soldered these to the SO239 and the second shield tag. I then installed the second SO239, and finally made the two connections where I could get to them (and see them, more to the point!)

It looks a mess, but there is sufficient clearance between the signal core and the braid at all points, and the joints are electrically sound. Basic continuity and isolation tests checked out OK.

Couldn't wait to get the lid on, so that no-one will ever see what's inside. I'm naturally self-critical, but maybe I'm being a little bit hard on myself having seen the inside of similar offerings from the likes of MFJ etc. Some of that stuff is properly embarrassing. Nonetheless, I'm going to re-make this entire thing at some point. I may try an alternative coax type, but the first thing I'll try is just to mount the toroids at 90° so that the coax 'tails' are naturally pointing straight towards the SO239 sockets. Physically there is just enough room vertically to do this, and the lid would then hold the guts firmly in place too.

Well, at least it works - that's the main thing

I've only performed some perfunctory testing to date. I'll do some objective testing over the next few weeks, but already I can notice a significant reduction in noise at the receiver. The choke is currently installed at the radio end of the feedline, but I may insert it in the middle (outdoors) and then also try it at the base of the antenna itself to see what difference it makes. I might even put one at either end eventually. Other immediate effects I've noticed, are seemingly much improved hit-rates to the Americas, Australasia and the Gulf states (although this could be improvements in the band conditions themselves on both 20m and 40m) using high duty cycle modes like FT8, JS8 and WSPR - with no discernible heating of the choke coils even at 100W input power. I'm sure I could hear more people on the 80m net this morning too, so I'm hopeful of some real-world improvements. Manually tuning my MFJ-949E was a lot simpler too. Touching the tuning knobs and chassis whilst making adjustments no longer causes a noticeable fluctuation in the reflected power levels, so I'm thinking that's down to less RF floating around the shack. I'll have to experiment with switching the choke in and out of line on various frequencies and report back, but it's looking good so far.

Here is a link to Steve Hunt's excellent paper: High Performance Common-mode Chokes - first published in Radcom Plus May 2015

Berni M0XYF